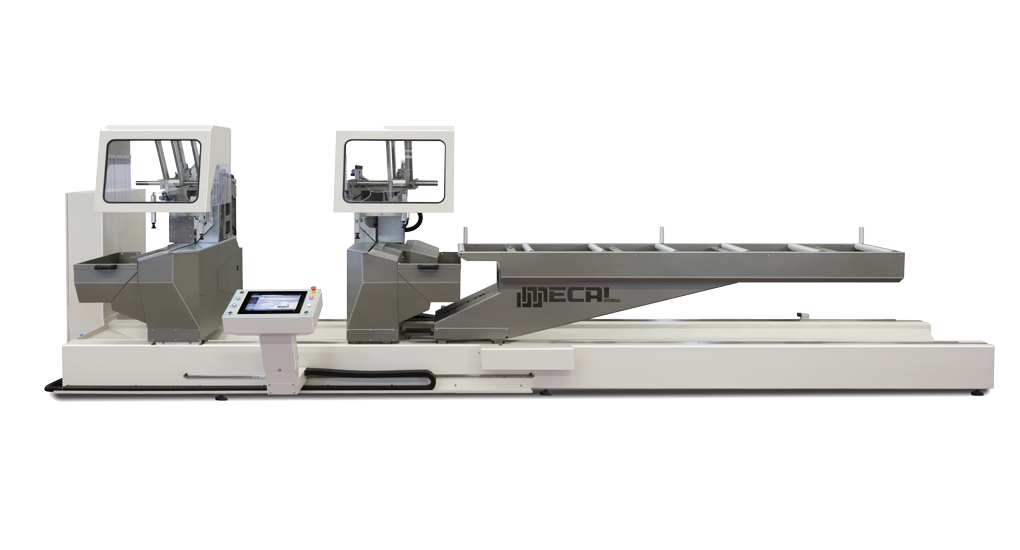

TDC 622 DynaCut

TDC 622 DynaCut

Double mitre saw with upward movement of the blades for radial cuts.

- Fixed cutting unit on the left. Powered positioning of the mobile cutting unit.

- 3 Axis managed through CNC, driven by brushless servomotors.

- Cutting table on fixed positions (90°). No change of rotation.

- Inclination of the cutting groups, with motorized control, on any angle between 45° and 90°.

- Standard cutting cycle with upward tilting movement of the cutting units. Radial cutting cycle, with the translation of the cutting groups in the operator’s direction combined with the upward tilting movement of the cutting units.

- Control unit with touch screen 15″, Magelis iPC industrial computer.

-

View Technical Data

The right to make alterations is reserved.Contemporary useful cutting (90°) mm 5000 / 6000 Cutting length (min. 90°) mm 470 Diameter of the sawblade mm 600 Sawblade bore mm 32 Speed of the rotating tool rpm 2400 Blade motor power kW 5,5 (x 2) Installed electric power kW 13 Overall dimensions (5 m. useful stroke) mm L/L=± 7930

L/W=± 2110

A/H=± 1870/2120Weight (5 m. useful stroke) kg ± 2800 Overall dimensions (6 m. useful stroke) mm L/L=± 8930

L/W=± 2110

A/H=± 1870/2120Weight of the machine (6 m. useful stroke) kg ± 3000